- Guides

- Tutorials

Useful tips

Good service is important to us - that's why we support you with useful tips and information on all aspects of ski service.

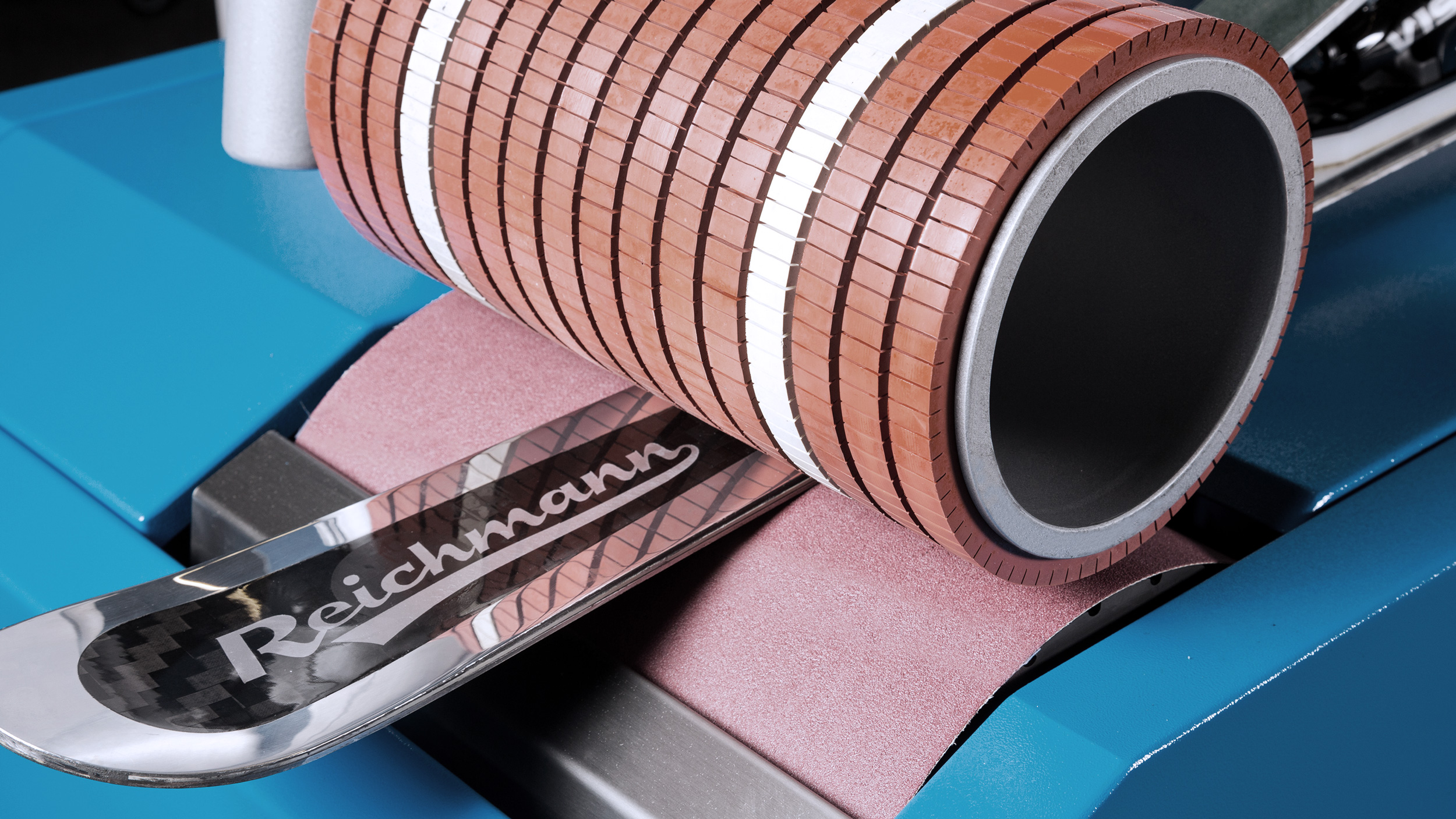

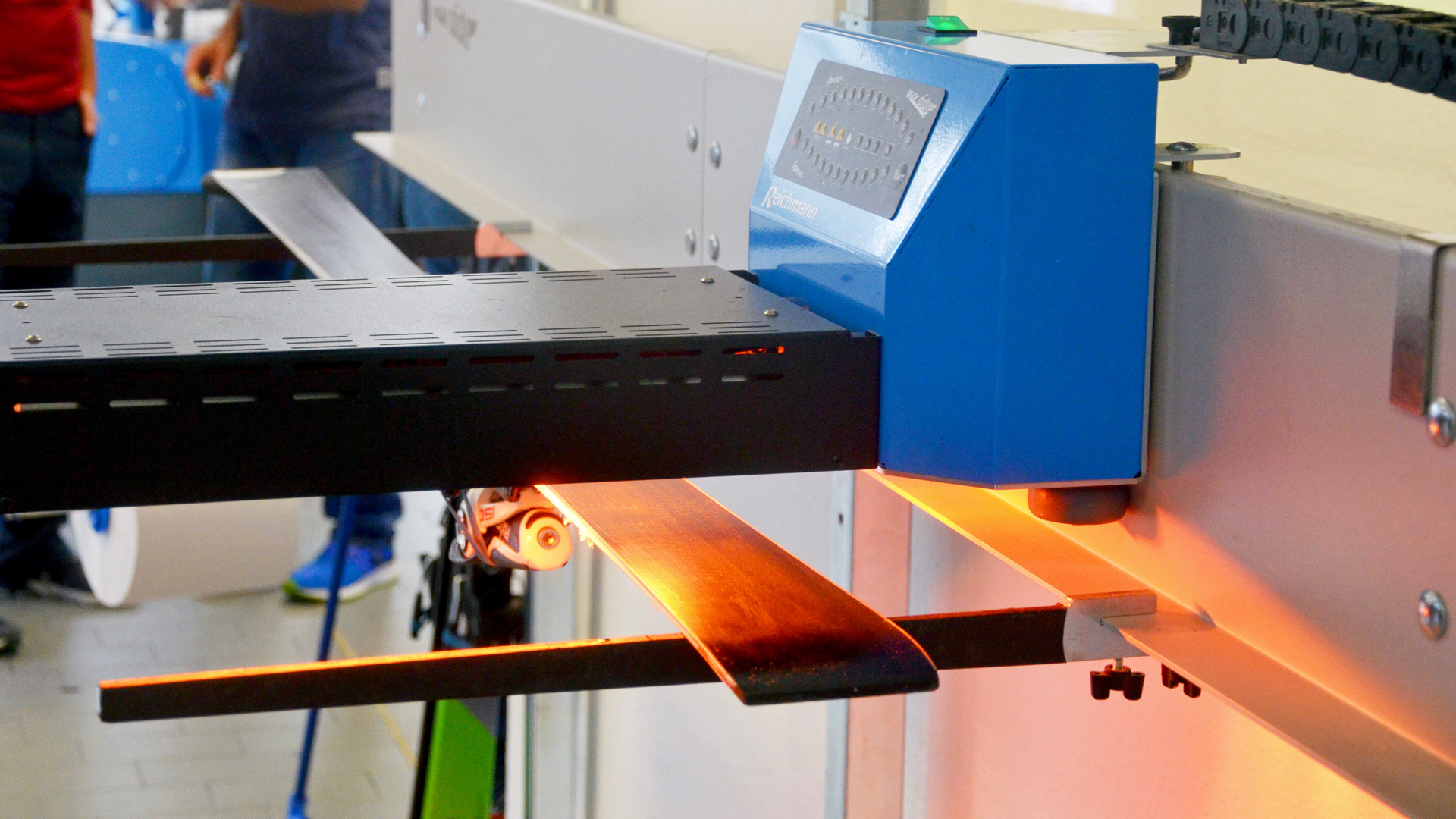

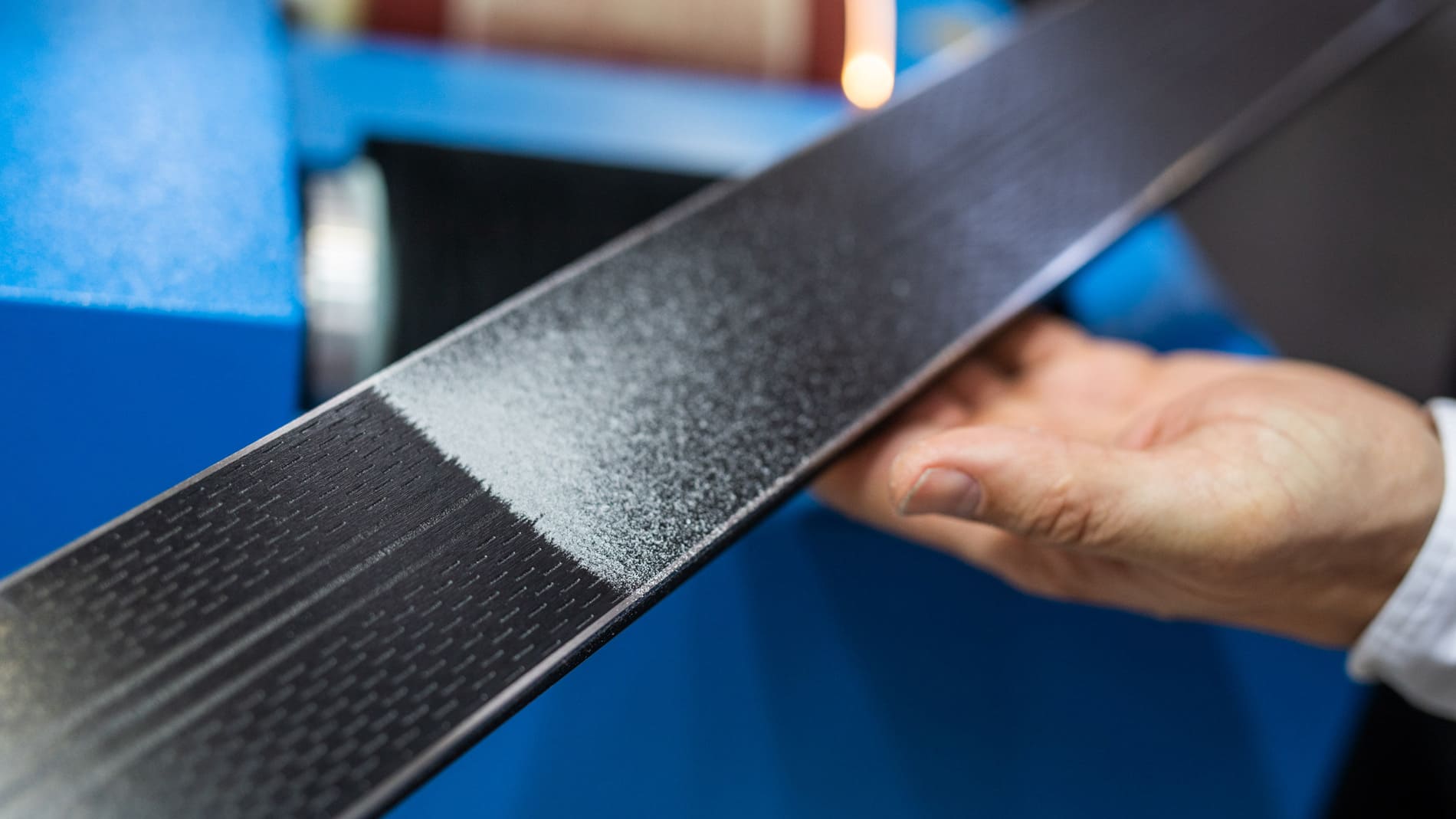

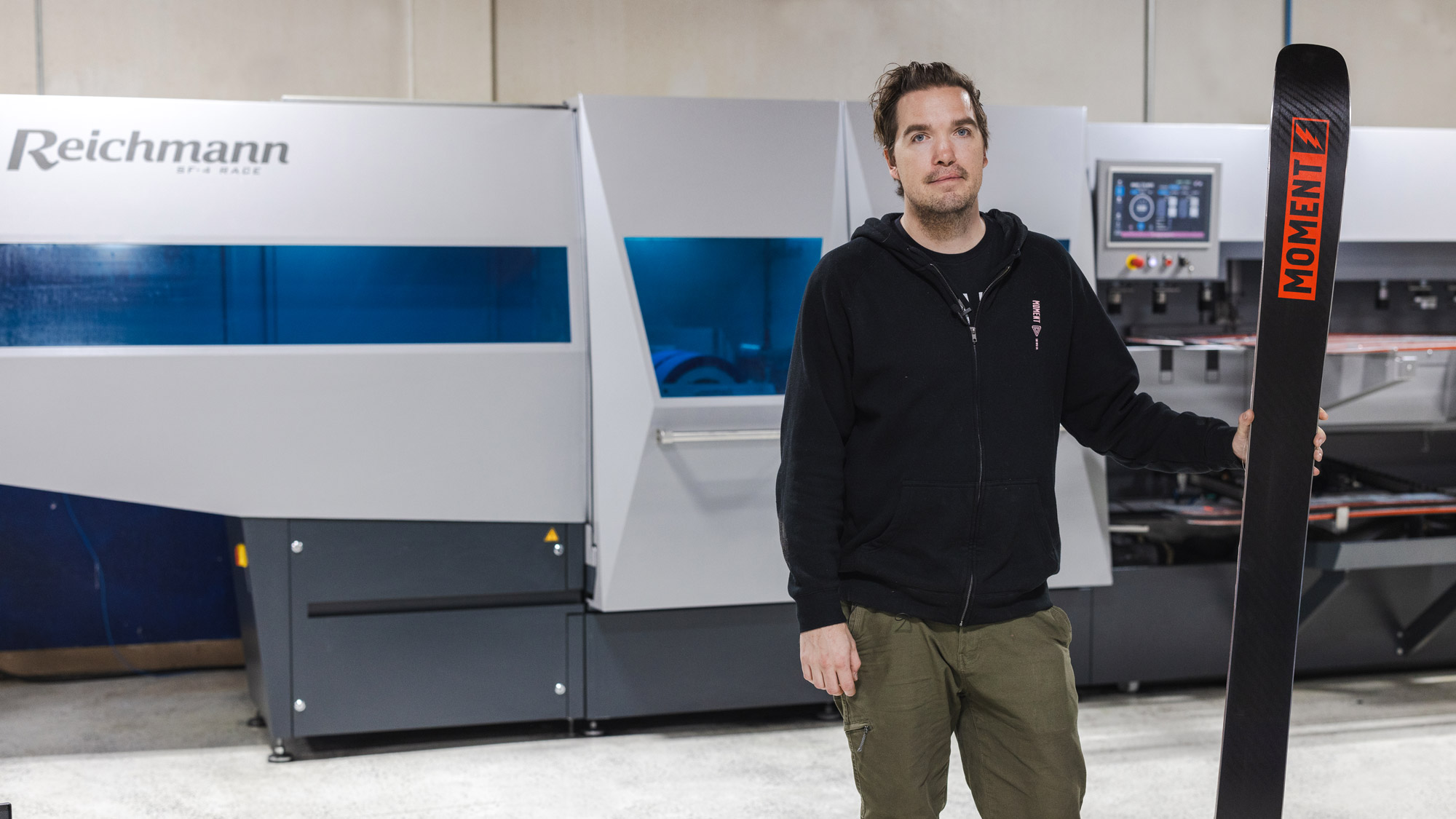

Customized service machines for the production environment at Moment Skis

Reichmann honors long-term employees

POLYMAT PRO wins ISPO Award 2023

Successful POLYMAT PRO premiere in Weissenhorn

Future-oriented solutions for the foundry industry inspire GIFA trade show visitors

World novelty: Innovative MAUS CAAT software optimises MAUS machines for top performance

Reichmann invests sustainable in new carport with photovoltaic system

Reichmann presents innovations at Interalpin in Innsbruck

New Depot lockers „Sequence“ unite elegance, individuality and functionality

Johann Konrad retires: Farewell after 48 years

Powerful cutting: KSB relies on power combination of TS 800 and TS 600

New software generation: Reichmann presents upgrade for SF-4 Race service robot

Schmiedeberger Giesserei extends automatic casting finishing with Maus 900

Reichmann presents solutions for sustainable and efficient ski service at ISPO

Installation of the first Maus 600 - Schmiedeberger Gießerei records over 50% time savings

Reichmann and c-Parts announce cooperation: Initial equipment of the new MAUS line with Muzzi grinding wheels

The new MAUS 600: automatic grinding „Made in Germany“

Reichmann Serviceworkshops: optimale Vorbereitung für den Saisonstart

Acquisition announcement: Reichmann takes over intellectual property of MAUS s.r.l.

Reichmann bids farewell to sales manager Karl Kustermann on his retirement

Time-efficient casting finishing of manhole covers with Reichmann universal chuck

A real alternative to ski wax – discover GigaGlide

How to repair the ski base

Online premiere of the Reichmann Slope Master

100 years of seniority at Reichmann company

Successful service training for sports shops and ski rentals

Abrasive cut-off machine TSF 500 M for cut-off grinding of investment castings

Video tutorials

In our video series "snowboard service with Martin Grüner" we show you step by step how a professional snowboard service is carried out by a real professional. From base repair to base grinding and edge grinding to waxing - get practical tips for board service at World Cup level. Martin Grüner is a service technician for the German National Snowboard Team and has been preparing the athletes' race boards for several years.

FAQ

Grain 80 for high abrasion: well suited for heavily rusted edges, a thick layer of wax on the base or heavily soiled bases.

Grain 100 for medium removal: for slightly rusted edges, a light layer of wax or slightly soiled coverings.

Grain 120 for low abrasion: slight rust film on the edges, minimally soiled coverings.

A complete cleaning of the machine is recommended once a year at the end of the season. On the last day of grinding, add the system cleaner to the old emulsion about 8-24 hours before pumping out. In this way, impurities and microorganisms in the lines and in the coolant tank are removed carefully and quickly. You can then dry, clean and store the machine for the next winter season. Also note the cleaning instructions in the operating manual.

In general, the water tank should be emptied and refilled every month. This prevents the formation of germs and fungi and creates a healthy and hygienic working environment. Alternatively, we recommend using a cooling unit. This allows the water in the coolant tank to be used all season long.

Your service machine will usually tell you when you need a new grinding stone. Modern service machines provide information at an early stage so that you can order a new stone until you have used it up completely.

The diamond should be visually checked regularly once a week and replaced if necessary. Pay attention to the marking on the diamond setting.

The required concentration can be found on the information on your grinding additive. Please check this value weekly using a hand refractometer and top up with water or grinding additive as required.

During the winter months, your service machine is exposed to high loads every day. Just like a car, your service machine needs regular maintenance and inspection. Regular service and good care ensure that your machine is always in top condition. This keeps your machine in operation for a particularly long time and ensures a high reliability.

No results.